💬 Introduction

A great product deserves great presentation.

Our custom packaging and gift box services turn your calculators into professional retail products or elegant corporate gifts.

Whether you’re targeting schools, offices, or promotional campaigns, our packaging solutions help your brand stand out — stylish, durable, and fully customized to your vision.

🎁 Packaging Solutions Tailored to Your Brand

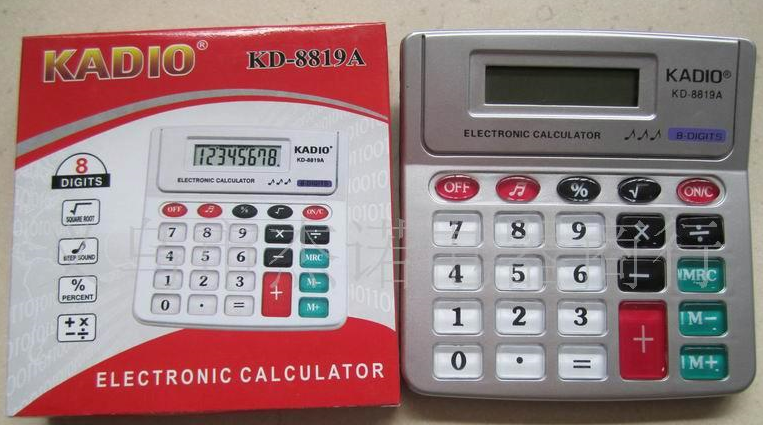

📦 1. Retail Packaging

Designed for shelf appeal and protection, retail packaging includes:

-

Clear blister packs and hanging cards for visibility

-

Printed paper boxes with brand details and barcodes

-

Eco-friendly kraft cartons for minimalist brands

We follow international retail packaging standards to ensure durability, visual consistency, and logistics efficiency.

🎨 2. Corporate & Gift Box Design

Make your calculators memorable with elegant corporate packaging.

Choose from:

-

Premium matte or metallic gift boxes

-

Velvet or foam inserts for protection

-

Embossed or UV-printed logos for a luxury finish

Perfect for company giveaways, business gifts, or limited-edition promotional events.

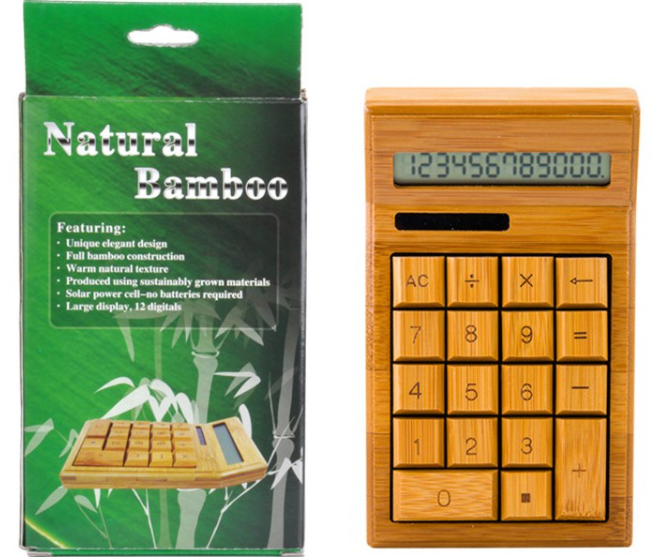

♻️ 3. Sustainable & Eco Packaging Options

Sustainability matters more than ever.

We offer recyclable and biodegradable packaging materials such as kraft paper, soy-based inks, and plastic-free coatings.

Eco packaging not only protects your product but also enhances your brand’s environmental reputation — ideal for modern corporate and educational clients.

🖨️ 4. Branding & Printing Customization

Every package is a communication tool for your brand.

We can print your logo, product specs, QR codes, and marketing messages directly on the box.

Color matching follows Pantone standards to maintain consistency with your product design.

Our OEM packaging process ensures precise alignment between calculator and box visuals.

🧠 5. One-Stop OEM Service

As a professional OEM calculator factory, we coordinate packaging design with your calculator model and logo style.

From template development to final print proof, our team ensures your packaging fits perfectly — visually and structurally.

We handle packaging sourcing, printing, assembly, and export packing all under one roof for efficiency and quality control.

For seamless customization, explore our Custom Logo & Branding page to integrate packaging with your full brand identity.

🌍 Applications

-

Promotional event giveaways

-

Retail packaging for e-commerce and stores

-

Educational kits and bulk school supplies

-

Corporate branding and holiday gifts

💬 FAQs

1️⃣ Can I print my logo and product details on the packaging?

Yes, we support full-color printing, embossing, and UV spot coating for brand visuals.

2️⃣ What packaging materials do you offer?

Options include paperboard, kraft, blister, foam inserts, and fully recyclable eco-paper.

3️⃣ Do you offer design support for packaging layout?

Yes, our graphic designers can help with dieline templates and layout suggestions.

4️⃣ Can I order packaging separately?

Yes, we can supply packaging independently or bundle it with calculator production.

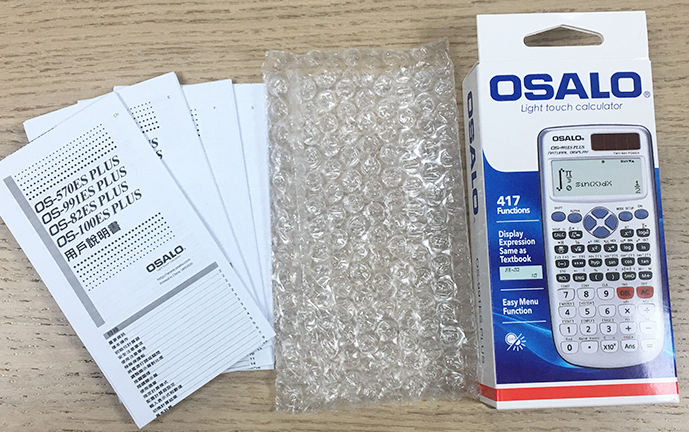

The following is a detailed introduction:

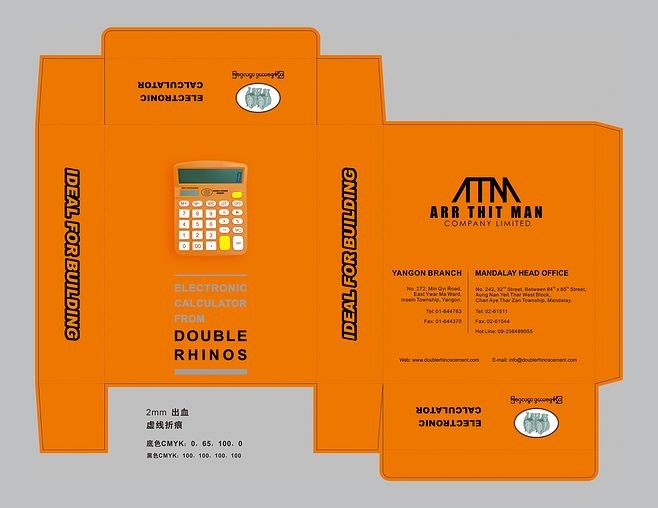

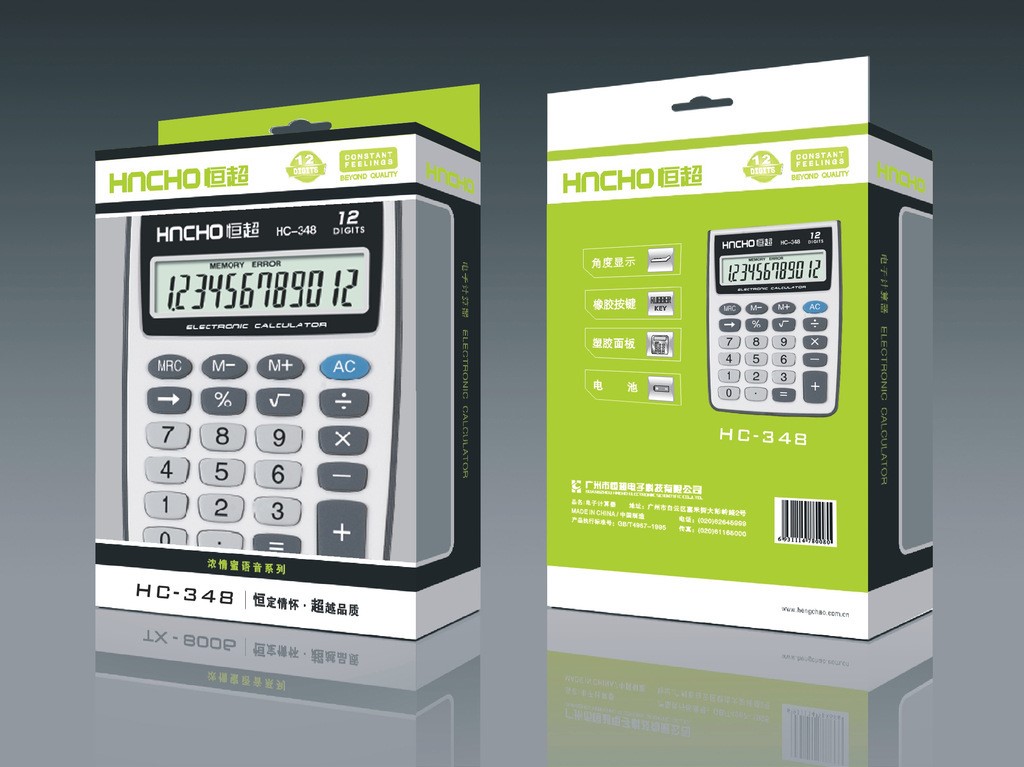

The regular packaging of the calculator is 1pc/opp Bag+color Box, and we can customize the color box according to customer requirements.

Color box printing-classification of color boxes:

Divided into two categories: facial paper and pit paper. Usually color box face paper is commonly used (called in Taiwan): pink paper, gray copper, cupronickel, single copper, gorgeous card, gold card, platinum card, silver card, laser card, kraft paper, etc.

There are 2 kinds of “white board with white background”: 1, white copper, 2, single copper. What they have in common is that both sides are white. The difference is “white copper”: one side is smooth and the other side is not smooth, that is, one side has a coated surface and the other side has no coated surface. The popular point is that the front side can be printed, but the reverse side cannot be printed.

“Single copper”: Both front and back sides have coated surfaces, both front and back can be printed. Gray-bottomed gray boards have this kind of paper, but they are not used on color boxes. Gray-bottomed whiteboards are so-called “gray copper paper”, which means that the front side is white and can be printed, and the back side is gray and cannot be printed. The general white card is also the “white background whiteboard” paper, which is just the abbreviation for general quotation, except for special white cards, such as platinum cards, silver cards, etc.

Powder gray paper, one side is white and the other side is gray, the price is lower, double powder paper is white on both sides, and the price is high.

The material of the color box is determined according to the shape and size of the product. Commonly used materials are: 280G powder gray paper, 300G powder gray paper, 350G powder gray paper, 260G powder gray paper mounting E pit, 260G double powder paper mounting E pit, etc.

According to the packaging weight of the product and the positioning of the product, the commonly used materials are: powder paper: generally 250g-450g; coated paper: generally 250g-400g.

Color box printing processing production process:

The color box printing production process is roughly as follows: carton structure design-→ draw printing outline drawing-→ decoration pattern design-→ plate making (film/screening)-→ printing-→ surface treatment (glazing, pressing Polishing/polishing, laminating)——→Mounting hole——→Die cutting (ie beer box)——→Gluing box (folding, nailing)——→Appearance inspection——→Packing